What is a waterproof breathable membrane and usage

Waterproof breathable membrane is a product application derived from membrane separation technology . Waterproof breathable membrane is a kind of membrane made by special process. It is a kind of membrane with selective permeability. Under the condition of its own characteristics, it can allow some gases smaller than the pore size of waterproof breathable membrane to pass through, but cannot allow other substances such as water droplets larger than the pore size of waterproof breathable membrane to pass through.

It is precisely because of the property of waterproof breathable membrane that some small molecules can pass through, but some large molecules cannot pass through the waterproof breathable membrane. Therefore, since the 1960s, waterproof breathable membrane has been rapidly develop. At present, there are mainly PTFE , Nylon , PES , PVDF , PP , NC, MCE , PETE and other filter membranes. Due to the good chemical stability and natural hydrophobic properties of PTFE, it is use for waterproof and breathable products.

Material

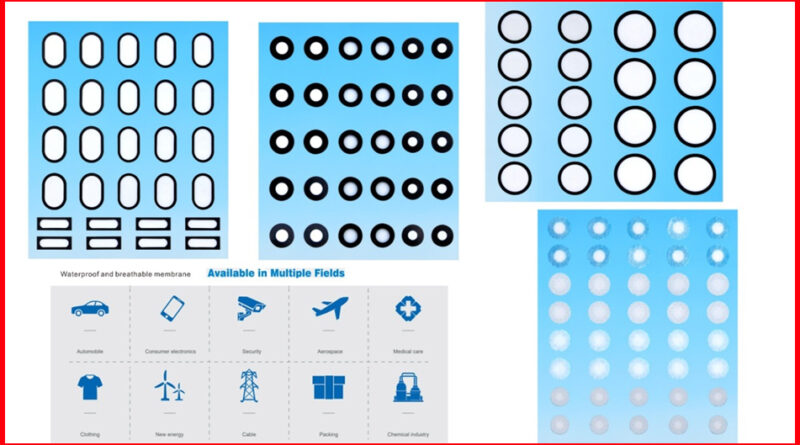

The material of waterproof breathable membrane is generally e-PTFE , which is a film produce by special process of polytetrafluoroethylene. Waterproof breathable membrane is mainly reflect in waterproof breathability, dust-proof breathability and anti-bacterial breathability. It is widely use in the fields of automobile, medical, environmental monitoring, packaging, protection of electronic sensor components, etc. Goel waterproof breathable membrane is mainly use for waterproof breathability of electronic products. It is call “breathable material” abroad.

The waterproof breathable membrane is mainly compose of a microfiltration membrane with a pore size between 0.1-10μm. For waterproof breathable membranes, water inlet pressure and air permeability are two very important values. Generally speaking, the two are in a competitive relationship, and high air permeability means low water inlet pressure. Waterproof breathable membranes are mainly divide into hydrophobic membranes and oleophobic membranes, and in general, oleophobic membranes are use. Since ePTFE has certain natural hydrophobic and oleophobic properties, it is sometimes wett and permeat when encountering some liquids with low surface energy such as alcohols, detergents, lubricants, etc. The surface energy of oleophobic membranes is lower and can resist the infiltration of these liquids.

Environment

Generally speaking, many devices and their applications require a relatively closed sealed environment that cannot be affect by dust, water, and bacteria. If the design is particularly close, the pressure inside the device will change under the objective conditions of changes in ambient temperature and latitude. Usually, this pressure change will have a certain agglomeration effect, which will damage the device shell and sensitive internal components. The use of ePTFE waterproof breathable membrane can continuously balance the pressure difference of the equipment, reduce component design costs, and ensure the reliability and safety of the product.

Now with the maturity of ePTFE waterproof breathable membrane technology, waterproof breathable membranes are mainly use in: communication equipment ventilation, communication equipment ventilation, small household appliances ventilation, automobile ventilation, medical ventilation, electronic sensor ventilation, packaging ventilation, among which packaging ventilation includes household packaging, agricultural packaging and industrial packaging and other product applications.